Building the Gypsywagen

The plan was to design and build a modern teardrop style trailer and then set out on an open ended road trip.

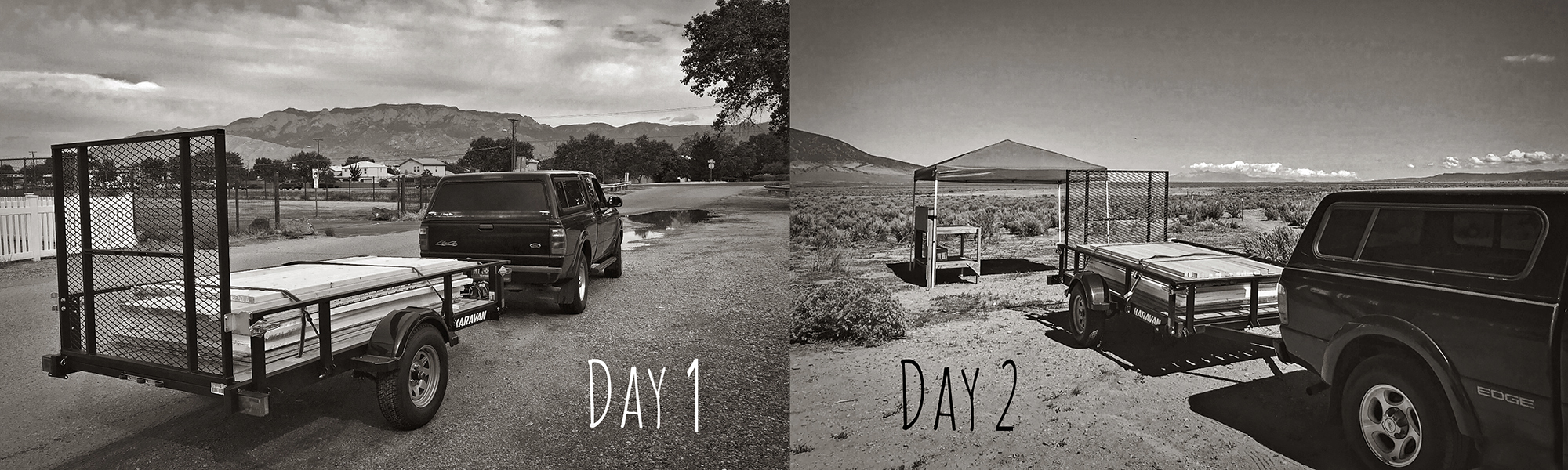

On a ranch in the high plains of Northern New Mexico, I’ve begun the build. I call this coach my Gypsywagen. First things first – purchase the 5’ x 10’ trailer bed and all the building materials in Albuquerque. Then doing the work in wide open spaces will require some structure. A pop up canopy, a 5’ x 10’ work table and a takeoff bench will do the job.

Next comes the framing of the coach.

ABOUT THE FLOOR…

It’s important to remove the fenders during the fabrication process.

The next step is to strip off the utility floor boards and prepare for the new, framed & insulated floor unit.

MOVING RIGHT ALONG…

Working in the open air of the southern Rocky Mountains is subject to inclement weather. Extreme high winds, rain & snow occasionally curtails the progress of the build. After some delays the floor unit is complete. It has 2×4″ framing with R13 insulation sandwiched between sheets of 3/4″ plywood. The bottom is coated with roofing tar. A robust floor will enhance the comfort and reliability of the whole structure.

Next, the framing of the walls.

IN THE OPEN AIR…

After a run of calm sunny days, high winds and rain have returned. But as weather permits progress is steady and the coach will soon be fully framed up. Then comes the finish work.

“I think heroic deeds were all conceived in the open air.” Walt Whitman

UNDER THE VOLCANO…

As the Gypsywagen takes shape, the looming mountain in the distance is a constant companion. Ute Mountain is a dormant volcano. At over 10,000 feet winter snowfalls quickly melt away . Hikers usually report an active culture of rattlesnakes on the Mountain, no doubt drawn by it’s warmth.

EVOLUTION…

People ask me, “why are you using 2x4s for framing? Don’t RVs have 2×2 frames?” The answer is, “They do.” But the insulation on those RVs is anemic… maybe R4 or R5. With a 2×4 frame, the insulation provides an R13 rate. Anyone who’s slept in an RV in sub-freezing (or sub-zero) temperatures will appreciate this aspect of the Gypsywagen’s engineering. Also, and this is important, this model I’m building is a prototype. The plan is for future “GWs” to have 2×4″ aluminum frames and .030 aluminum skins – a savings of many hundred pounds per vehicle. As an old English teacher of mine used to say, “Things have to e-vo-lewt!”

COMPACT & MOBILE…

Details… framing, wiring, paneling, and more snow. Colder weather continues to advance into these parts. Work on the Gypsywagen is interrupted by snow days. Even so, the coach should be ready to roll out of here before serious winter sets in. Moving on to southern Arizona, some of the finish detail work will get done in a gentler climate. Compact and mobile is the operating principle of this creation. It seems right that even in it’s beginnings, the principle applies.